Our list of services include:

Our precision manufacturing engineering services include:-

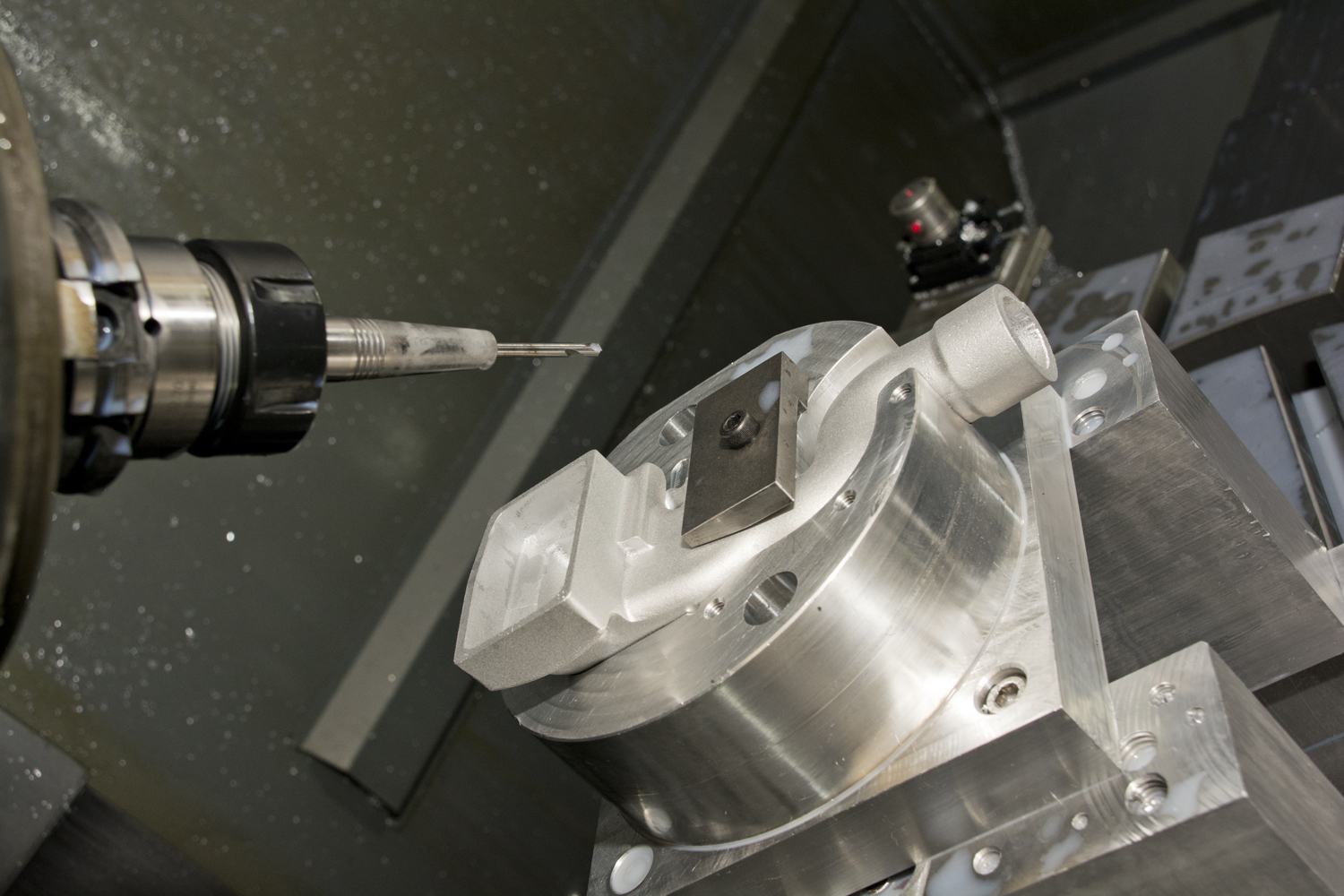

CNC 5 axis machining, CNC milling, 3d multi axis and mould machining equipment.

5 Axis Milling

Why IES Machining Ltd benefit from 5-axis machining: –

- The machines ability to machine complex shapes in a single set-up.

- Reduces the setup time

- Decreases production times

- Eliminating multiple set-ups

- Cycle times and errors are reduced

- The accuracy is improved as the same datum reference is used throughout the manufacturing process.

- It offers maximum milling performance, highest machining performance and excellent accuracy with its extreme rigidity and stability.

Our 5-axis machining centres are developed to make complex parts on one machine, we can produce these parts by machining multiple sides of a part simultaneously in one setup. The process reduces cycle times, increases accuracy, and increases the overall speed of production. 5-axis machining is ideal for producing complex work pieces with strict manufacturing requirements.

Moulds & Assembly

Lemoine Real Time Machining

Although 5-axis milling is one of the most challenging forms of CNC machining, Lemoine RTM makes it possible for programmers to generate 5-axis NC programs quickly and easily, with short machining times and high quality surface finish. 5-axis programming does not need to be time-consuming or unreliable. Lemoine RTM due to its simple and user-friendly programming, collision detection and simulation gives Intelligent Engineering Solutions the edge over its competitors allowing tool paths to be generated quickly with minimum downtime

Quality & Inspection

At IES Machining quality and service are the foundation from which the business has evolved. We have an ethos of continuous improvement and are dedicated to maintaining and continuously improving quality standards. Our quality system also ensures we are striving for high levels of service to meet our customer requirements. Through a dedicated inspection department our CMM`s are installed with the latest QCT inspect software checking intricate components. We also have a comprehensive selection of equipment to ensure all parts are fully checked and passed. All parts go through a thorough inspection process before despatch ensuring quality standards are maintained. Depending on your requirements we can offer a wide range of inspection formulas to suite the product, ranging from full inspection of every component and feature though to first off or parts off according to agreed variance requirements, i.e., 1 in every 50. During every stage of manufacture IES Machining emphasise attention to detail and quality. Quality control is essential to the success of the company and all company personnel are aware of the importance of meeting customer’s requirements and the management encourages teamwork so that everybody can contribute to the success and improvement of the company. Our key objectives are the elimination of customer complaints and the increased satisfaction of our customers measured by the continued expansion of customer numbers and the continued improvement of our quality system.

Reverse Engineering

We can reverse engineer components, dismantling assemblies and both replicate component function and improve performance characteristics then prepare technical drawings for remanufacture.

Prototype Engineering

We undertake prototype machining of billet machined components, machined castings and assemblies. Working closely with the customer we can assist in design development advising on best machining practices, materials and production techniques. As a small dynamic company we are also happy to manufacture these usually at short notice.

One Stop Solution!

IES Machining provides a one-stop solution, allowing you to spend more time on your core business activities, safe in the knowledge that we can oversee the whole process from design through to delivery. We offer a vast range of component supply solutions as well as project management.

Project Management Service

We know that your project is important that is why we provide a management service from design through to delivery. We provide you with the peace of mind that your project will be produced on time and on budget!

Contact Us

Contact us here for further information